Significant improvement in operational efficiency through real-time monitoring and predictive maintenance.

Dramatic decrease in unplanned downtime through predictive maintenance and real-time alerts.

The Challenge

A leading manufacturer needed to modernize their factory operations through IoT integration and real-time analytics. The existing system lacked visibility into machine performance and couldn't predict maintenance needs effectively.

Key Requirements

- Real-time monitoring of manufacturing equipment

- Predictive maintenance capabilities

- Integration with existing ERP systems

- Mobile access for floor managers

- Minimal disruption during implementation

Our Approach

Using our micro-transformation methodology, we:

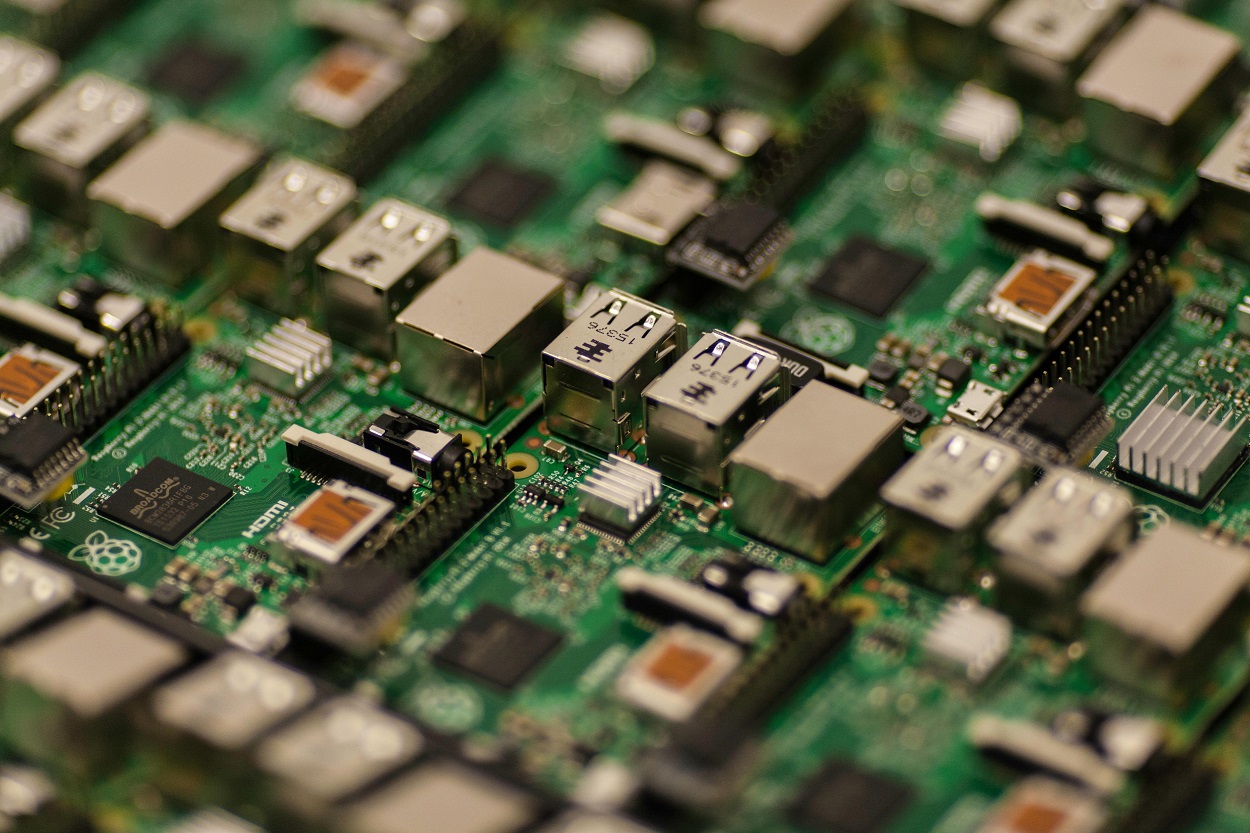

- Implemented IoT sensors on critical equipment

- Developed real-time analytics dashboard

- Created predictive maintenance models

- Built mobile applications for floor management

Technical Solution

The solution leveraged modern IoT and cloud capabilities:

- Azure IoT Hub for device management

- Real-time data processing pipeline

- Machine learning for predictive maintenance

- Mobile-first dashboard interface

Technologies Used

Key Outcomes

- Real-time visibility into machine performance

- Predictive maintenance saving millions in downtime

- Mobile access for floor managers

"The transformation of our factory operations exceeded our expectations. The real-time insights and predictive capabilities have revolutionized how we manage maintenance."

Ready to Transform Your Platform?

Start your transformation journey with a focused micro-transformation that delivers immediate value.